I was thinking about building a radio controlled car from scratch and using a chainsaw engine for

power now for some time. It took me a while but I eventually did it and it's

pretty cool. And when you see and hear it, it's more cool.

There's too much power and it's a little hard to control

but that's okay, it's supposed to be extreme. Here's how it went.

|

Here is a photo of the basic but

somewhat stripped chainsaw. The air filter cover is

off so you can see the carb and the muffler is also

off which resides to the left of the clutch. |

|

Here is the other side of the

motor. It's pretty clean and the compression seems

good. No broken parts as far as I can tell. I'll

still rebuild the motor however. |

|

Here is the clutch that comes on

it. The dumb chainsaw chain makes this set-up

useless. I'll have to buy something or get dad to

rig something for me. |

|

I bought the rear bushing drive at

the hardware store for $19.00 and it should work

fine. Nice and solid! |

|

Here's just another angle. You can

see how the chain will go and if I get brave I'll

put shocks on the back somehow. I have to be able to

control this thing otherwise Brian (my cousin) will

crush me. |

|

I'm going to make the frame out of

this aluminum square tube. It's strong and nice and

light and looks cool. I will probably have some sort

of platform though because otherwise the frame may

be kind of bendable. |

|

On day two I rebuilt and cleaned

the engine. I had every nut and bolt off of the

thing. I decided to replace the rings since they

looked a little worn. |

|

Here's the motor all reassembled

and it lost some baggage from the previous day.

Notice the mounting plates on each side. |

|

Since I stripped off the outer

casing I'm left with a problem of figuring out a way

to start this thing. I'm thinking about using a

drill...(you'll see) |

|

This was the part that scared me

the most since I needed to find a sprocket assembly

small enough for this. Plus the clutch had weird

teeth on it. Thankfully my dad does tool and die for

a living. |

|

This is a close-up of the custom

parts my dad made. The sprocket is is from a bicycle

and the hub is custom tool and die work by my dad.

He also got a small sprocket welded onto the clutch.

Worries are over. |

|

Since day 1 I have redesigned the

drive axel. Firstly I moved from a steel axel to an

aluminum one and I also decided to go with bearings

instead of bushings. |

|

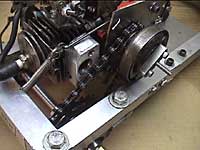

She begins to take shape. The frame

is made of aluminum and bolted together with

stainless steel nuts and bolts. I built this part of

the frame twice because I first used too thick of

aluminum square tube. Now it's much lighter |

|

Figuring out the best way to mount

the engine was hard. I spent days just looking

things over and finally decided on this design. It's

close to the rear and still close to the ground.

Figuring out those mounting plates was a challenge

|

|

Here's a view from the other side.

I'm hoping to start the motor somehow using the axel

that the flywheel is mounted to. |

|

Maybe I didn't need another shot of

the same thing but this gives me a chance to say hi. |

|

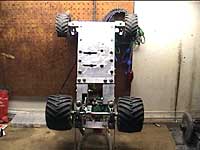

I put the tires on and am starting

to see this thing take shape. I know it will be a

little high off the ground but that's ok. Maybe it

will be more of a monster truck. Since I don't have

any suspension it may not be wise to go too fast

anyhow. |

|

Oh yea - these tires are not the

ones I'm going to use. I have some monster truck

tires on order from the hobby shop They are 6" high

and 4" wide. I also have a heavy duty servo ordered

and just bought the receiver today. |

|

OK folks - I've got some 6" high

USA-1 tires and rims for this thing. They've got a

unique mounting set-up that should be very solid.

They're not quite as stiff as I'd like but they'll

do. |

|

The tire has a hex pattern molded

into the rim that fits snug over this part my dad

made which slides over the axel and is secured with

a cotter pin. Once bolted down Those tires are going

nowhere. |

|

Here's what it looks like with the

tires mounted. It sits a little high but that's good

because it means MUD BOGGING! The grip these tires

get is amazing especially with the POSI rear end. |

|

Here you can see that the chain is

on and the set-up is rock-solid. Better than I even

imagined. I was having trouble with the clutch

self-tightening against my mounting plate so my dad

made that part that sticks over the end and holds

the shaft in place. |

|

The muffler is another sticky part

to this project. Again, my dad made this custom part

that allows clearance for the chain yet accommodates

the large pipe - plus it's made of lightweight

aluminum. |

|

Yet another problem area. This is

the chamber pressure unlock key. You pull this pin

out and it makes the flywheel easy to turn and and

the motor starts easier. It works like a charm and

I'm a genius for actually figuring this one out. |

|

And since you're curious I'm

starting this beast with a plain old drill. I've got

a socket attachment that just slides over this nut.

You fire the drill and the flywheel spins..

it actually starts. You'll have to wait to see those

pictures :) |

|

And once it's started I've got this

handy kill switch to put it out. I'm not sure if

this is the best spot for the switch but for now it

works fine. Do you like the HI-TECH sticker on the

back? At the American Science Center they have these

aluminum stickers for less than a penny a piece. |

|

Front suspension and steering time.

The conception was harder than the actual building

of it. I got this idea from looking at a full size

go-cart. The block you see rotates and glides up and

down creating the "suspension". Of course my dad

built the block and tapped the holes for me. |

|

Here's a picture of the oversize

1/4 scale servo (133 sq oz of torque). I originally

bought a $75 servo that ended up breaking so I found

this stronger one and bigger one for only $30...I

could kick myself for not finding it sooner. You can

also see the receiver mounted on top of the servo in

this picture. |

|

Here's looking at the front of the

car where you can see the servo with servo-saver and

the tie rods attached to it. I slipped stainless

steel tubing over the rods because they were too

flimsy and bent easily. |

|

Just another shot of the steering

mechanism from a different angle. The ground

clearance in the front could be better but I have

options for that if I need to adjust it. |

|

A top view of the steering and

associated structure. I've had problems running into

objects and bending it. So, as long as I don't crash

this set-up should work perfect. |

|

On day 6 I'm just adding the

finishing touches but some of these proved to be the

most troublesome and time consuming. Here is what I

figured out for an air filter - just a piece of

square aluminum from the carb and a foam filter

zipped to the end. |

|

Finding a gas tank was/is

difficult. This one is used for model airplanes.

It's not the right kind since I need one that has a

actual screw on cap not one of these pressurized

jobs. But it works fine so until I find something

better I'm sticking with it. |

|

The throttle after two re-works now

works perfectly. It's quick and responsive and seems

very solid. You can also see the on/off switch for

the servos in this shot. |

|

The other side of the servo cable

ends here at the carburetor where the throttle is

controlled with precision and no static or glitches

in performance. |

|

I may have mentioned this before

but I was having trouble with the clutch spinning

off the threads so my dad built this little stopper.

Works like magic. |

|

To prevent this bad boy from

flipping over and doing wheelies I built this

wheelie bar. Attached to it is the roll cage. Which

looks pretty cool too :) |

|

Well folks it's all done and my oh

my does it look good. However, I have a biased

opinion so you may think differently. |

|

Just in case you're interested in

seeing what it looks like from the bottom here it

is. It gets a little dirty but not too bad. The

solid plate across the bottom does it's job pretty

well. |